cylinder hone question

#1

cylinder hone question

Hey I have all six pistons out the block, and I measured the tops of cylinders with a veneer caliper and they measure up to 95.5mm as of now. If I get 95.5mm HR pistons with rings, will I be ok with just honing the cylinders to get a good crosshatch, or must I get the cylinders bored up .5mm and then honed?

I'm asking because I can get some used 95.5mm HR pistons and valve springs and ru oil pump pretty cheap. And I bought a stoned engine cylinder honer. lol a stoned honer. Can I put this honer in my drill and if I use enough oil(what is enough?) can I hone myself? This machinist in the city wants to charge me 180 for just the hone and if I can get by without paying that then I would want to! And I'm afraid that he'll hone to 96mm or close to it. Anyone help?

I'm asking because I can get some used 95.5mm HR pistons and valve springs and ru oil pump pretty cheap. And I bought a stoned engine cylinder honer. lol a stoned honer. Can I put this honer in my drill and if I use enough oil(what is enough?) can I hone myself? This machinist in the city wants to charge me 180 for just the hone and if I can get by without paying that then I would want to! And I'm afraid that he'll hone to 96mm or close to it. Anyone help?

#2

I don't know about the HR pistons, but if you don't know how much oil to use or if you can hone yourself I would leave that alone. Pay the $180. Thats nothing and will guarantee you a quality honing job and you know it will be within specs and done correctly. Just my advise. Cant be cheap when building an engine. You might go through all that to save $180 and put it together and the thing fail......not worth the $180 you saved. Just my opinion.

#3

It depends on the pistons and how accurate you want to be. There are 3 (IIRC) stock/non-over-bore piston sizes for VQ's DE's or HR's - each block has which size piston is in each cylinder. The pistons themselves aren't stamped though..i don't think.

I'm running clearanced HR's and I just did a light hone (local machinist charged 72 dollars cdn, on a sunnen too) but its still being pieced together so I can't tell you the results haha. I think he said it only took it down 3/4 of 1 thousandth - which is minimal. Bassically you want to measure the pistons and measure your bore (measure the point where the rings come to their peak as thats where the most wear is) - and measure deeper down too if you have a guage for it. If you end up getting it bored out - get the pistons first and provide those - and make sure you find a place that can do it with a plate - otherwise it can warp the block if they aren't super patient.

I'm running clearanced HR's and I just did a light hone (local machinist charged 72 dollars cdn, on a sunnen too) but its still being pieced together so I can't tell you the results haha. I think he said it only took it down 3/4 of 1 thousandth - which is minimal. Bassically you want to measure the pistons and measure your bore (measure the point where the rings come to their peak as thats where the most wear is) - and measure deeper down too if you have a guage for it. If you end up getting it bored out - get the pistons first and provide those - and make sure you find a place that can do it with a plate - otherwise it can warp the block if they aren't super patient.

#4

okay, so if I hone it or end up getting it honed, it shouldn't make it bigger enough to get the 96mm pistons. I don't know I'm in NE, and everywhere around here besides the dealership mostly caters to domestics, not imports. (I can't even find a valve spring compressor locally that works on these heads!) I find the mechanics at the dealership incompetent for the most part and they'll charge a lot more. I guess I can give the cylinder hone specs to the mechanic.

#5

Just ask for a very light hone - and the bore should be pretty close to within spec assuming the bores aren't already worn right down. All you really want is a new crosshatch pattern to give the new rings something to bed into. But - like I said, if the pistons you're putting in (even if stock) - might already be ever so slightly bigger than those currently in your DE - so sometimes a hone will get you even better tolerances - regardless you'll want to measure each piston and bore after the hone and match them up as good as you can.

Just to clarify - stock pistons come in three sizes Grades 1, 2 and 3. But you can also order OEM bigger sized pistons too @ 0.20 over, see this for reference. (http://www.courtesyparts.com/kb_sear...cat=1)(usually .

For a valve spring compressor, get the blue point tool - snap on sells it, it's reasonably price and works really really well. Looks like this:

Just to clarify - stock pistons come in three sizes Grades 1, 2 and 3. But you can also order OEM bigger sized pistons too @ 0.20 over, see this for reference. (http://www.courtesyparts.com/kb_sear...cat=1)(usually .

For a valve spring compressor, get the blue point tool - snap on sells it, it's reasonably price and works really really well. Looks like this:

#6

Just ask for a very light hone - and the bore should be pretty close to within spec assuming the bores aren't already worn right down. All you really want is a new crosshatch pattern to give the new rings something to bed into. But - like I said, if the pistons you're putting in (even if stock) - might already be ever so slightly bigger than those currently in your DE - so sometimes a hone will get you even better tolerances - regardless you'll want to measure each piston and bore after the hone and match them up as good as you can.

Just to clarify - stock pistons come in three sizes Grades 1, 2 and 3. But you can also order OEM bigger sized pistons too @ 0.20 over, see this for reference. (http://www.courtesyparts.com/kb_sear...cat=1)(usually .

For a valve spring compressor, get the blue point tool - snap on sells it, it's reasonably price and works really really well. Looks like this:

Just to clarify - stock pistons come in three sizes Grades 1, 2 and 3. But you can also order OEM bigger sized pistons too @ 0.20 over, see this for reference. (http://www.courtesyparts.com/kb_sear...cat=1)(usually .

For a valve spring compressor, get the blue point tool - snap on sells it, it's reasonably price and works really really well. Looks like this:

thanks for postin that bluepoint tool also, but yesterday I bought a c-clamp type off ebay, I think it will work because it looks like can reach into the heads pretty good.

#8

Which bolts? You need an E14 socket (external torx) for those main studs (get atleast half inch) if you're pulling the crank - the rod bolts need a 12-point socket, I think they were 10mm but I'm not 100% sure, pretty sure i found the answer on my350z.com...

With regards to piston grade - the compression would have more to do with the fit/break in of the rings considering how small the differences are in grade- but if you're revving the **** out of the engine, it's better to be on the loose side anyways.

You might lose a little bit of compression/power - and worse case scenario get piston slap on cold starts + be more prone to oil burning, but thats the risk of being DIYer and not having all the high tech tools.

Before you drop the pistons you might want to use a feeler guage and check the gaps between the rods/crank/thrust bearings (shows you how to do it/the specs in the FSM). Any extra resistance bassically introduce more pumping/friction losses and looses power. (it's an old skool trick where if you pull the crank and swap the bearings, you can measure the force it takes to spin the crank freely - the idea is you can gain a fair bit of free horsepower just by reducing that friction point)

With regards to piston grade - the compression would have more to do with the fit/break in of the rings considering how small the differences are in grade- but if you're revving the **** out of the engine, it's better to be on the loose side anyways.

You might lose a little bit of compression/power - and worse case scenario get piston slap on cold starts + be more prone to oil burning, but thats the risk of being DIYer and not having all the high tech tools.

Before you drop the pistons you might want to use a feeler guage and check the gaps between the rods/crank/thrust bearings (shows you how to do it/the specs in the FSM). Any extra resistance bassically introduce more pumping/friction losses and looses power. (it's an old skool trick where if you pull the crank and swap the bearings, you can measure the force it takes to spin the crank freely - the idea is you can gain a fair bit of free horsepower just by reducing that friction point)

#10

Mechanically it could be done with it in if the machinist is careful...but think of all the fine metal particles getting into your bearings - you could seal it up, but then you're carrying around a heavy-*** block and explaining silly ideas to professionals.. : ) If I was honing it myself I'd probably try anyways, hahah

$$ wise, the only cruddy part about dropping the crank when you're already this deep in is the main seal - you could try re-using but it would suck if it didnt work out.

$$ wise, the only cruddy part about dropping the crank when you're already this deep in is the main seal - you could try re-using but it would suck if it didnt work out.

Last edited by bamboomerang; 01-08-2012 at 08:02 AM.

#12

How is the existing crosshatch on the block? Sometimes its better to leave an intact crosshatch pattern alone than to throw your own pattern in there along with it. The plateau finish that flex-hone type tools give after boring is primarily to knock the jagged peaks off to help with sealing and longevity but the primary purpose of the crosshatch is to hold oil, not to help with break-in. If the cylinders are glazed over, then a rehone is definitely indicated but otherwise, I'm not sure its necessary or even beneficial. I guess I'm not a fan of doing things "just because".

#13

The crosshatch is kinda there in some places, and not there on others. Since I'm going to be using USED HR pistons/rings, depending on the condition of the rings, should I hone it lightly? I don't know the specks of the HR pistons' diameters I assume the same as the DEs?

#14

It should be the same 95.5mm spec as the DE however as bamboomerang noted there are 3 different grades even at that spec. They are probably middle of the road grade 2's as I believe the other ones are in case there are slight machining variations IMO. As for the crosshatch not being there in some places, I'd indeed hone it. Just wondering though, is a new ring set cost-prohibitive?

#15

It should be the same 95.5mm spec as the DE however as bamboomerang noted there are 3 different grades even at that spec. They are probably middle of the road grade 2's as I believe the other ones are in case there are slight machining variations IMO. As for the crosshatch not being there in some places, I'd indeed hone it. Just wondering though, is a new ring set cost-prohibitive?

Thanks So the pistons themselves should be good, grade 2's?

I guess i can get new rings, are the rings the same throught grades 1-3? I have heard/read that the cylinders actually break-in to the rings, not the other way around? I assume this is because rings are probably made from spring steel and the cylinders are aluminum..Off topic-I gotta get a .04"cometic HG and possibly new head bolts and crankshaft bolts-good idea right?

#16

Thanks So the pistons themselves should be good, grade 2's?

I guess i can get new rings, are the rings the same throught grades 1-3? I have heard/read that the cylinders actually break-in to the rings, not the other way around? I assume this is because rings are probably made from spring steel and the cylinders are aluminum..Off topic-I gotta get a .04"cometic HG and possibly new head bolts and crankshaft bolts-good idea right?

I guess i can get new rings, are the rings the same throught grades 1-3? I have heard/read that the cylinders actually break-in to the rings, not the other way around? I assume this is because rings are probably made from spring steel and the cylinders are aluminum..Off topic-I gotta get a .04"cometic HG and possibly new head bolts and crankshaft bolts-good idea right?

The cylinders are NOT Al. They are cast iron liners or some other alloy.

Clearances are what matter here. You don't want clearances that are too tight nor too loose, but you should err on the side of loose on a performance motor. Like nismology said, I'd go with a grade 2, but measure the end ring gap to ensure it's in range.

As for ring break-in...

"When a cylinder is new or overhauled the surface of it's walls are honed with abrasive stones to produce a rough surface that will help wear the piston rings in. This roughing up of the surface is known as "cross-hatching". A cylinder wall that has been properly "cross hatched" has a series of minute peaks and valleys cut into its surface. The face or portion of the piston ring that interfaces with the cross hatched cylinder wall is tapered to allow only a small portion of the ring to contact the honed cylinder wall. When the engine is operated, the tapered portion of the face of the piston ring rubs against the coarse surface of the cylinder wall causing wear on both objects.

Each tiny groove acts as the oil reservoir holding oil up to the top level of the groove where it then spreads over the peak surface. The piston ring must travel up and down over this grooved surface, and must "hydroplane" on the oil film retained by the grooves. Otherwise, the ring would make metal-to-metal contact with the cylinder wall and the cylinder would quickly wear out."

Last edited by Weimar Ben; 01-13-2012 at 09:15 PM.

#17

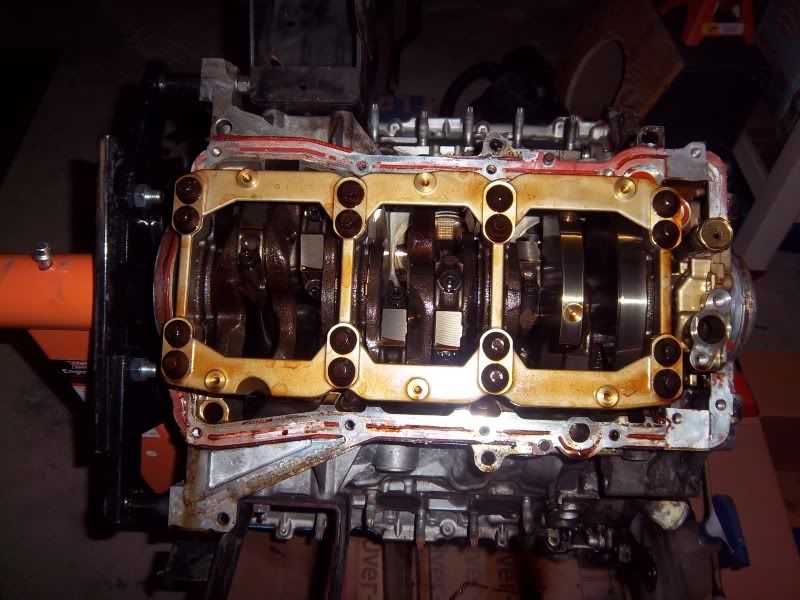

A little off topic, but I see you used red RTV on the oil pan. I prefer grey because it's what the OEM uses and it seems more tenacious and holds up to torque better than the red. I don't see any compelling reason to use the red. Red is a first generation 1970-1980 gasket maker.

Grey makes such a strong bond with aluminum, it almost eliminates the need for bolts.

Grey makes such a strong bond with aluminum, it almost eliminates the need for bolts.

Last edited by Weimar Ben; 01-13-2012 at 09:55 PM.

#18

thank weimar, the red gasket was already on there, it was still very strong!

Grey you say lol I'll get that for when I rebuild, it's so cold lately that I dont really like working. I still gotta hone the six, then get the new piston rings. I didnt ask the guy if they were fi or not;feel dumb now

Would assembling the engine in close to freezing temps be a good idea with all the tourqe-angling and stuff lol...

Anyway, After the hone or glaze-breaking, I'll check piston ring gap. flex hone is better at breaking glaze or thats all its good for. if its good within spec then in they go, but the crankshaft journal bearings are kinda worn even though the crankshaft spun so smooth. i was lookin at a way to determine what replacements to get from the block but still need to learn how.

Grey you say lol I'll get that for when I rebuild, it's so cold lately that I dont really like working. I still gotta hone the six, then get the new piston rings. I didnt ask the guy if they were fi or not;feel dumb now

Would assembling the engine in close to freezing temps be a good idea with all the tourqe-angling and stuff lol...

Anyway, After the hone or glaze-breaking, I'll check piston ring gap. flex hone is better at breaking glaze or thats all its good for. if its good within spec then in they go, but the crankshaft journal bearings are kinda worn even though the crankshaft spun so smooth. i was lookin at a way to determine what replacements to get from the block but still need to learn how.

#19

I JUST measured all the bores bottom middle and top, with a dial bore gage they are out of whack each about .001", and only .0004" is allowable in between grades, so thats very minimal change Im just going to hone it and measure again after the hone and hope that can get me better results, just waiting on the hone and oil to arrive.

#20

I just honed the cylinders, and I don't really have the 'ideal' 60 degree crosshatch, more like 45-50 degree, but will that matter?

The cylinder bores didn't need to be ridge reamed, so I guess that means that the piston rings hadn't really worn down the bores...

I'm about to put HR pistons in, and I got a feeler gauge that goes down to 0.0025", but the fsm states that the piston to cylinder bore clearance is to be between 0.0004 - 0.0012"? The 0.0025" feeler gauge is TWICE that thickness and it's paper-thin steel, so how do I measure? Are there some other kinds of feeler gauge that go down to 0.0004 - 0.0012" I searched on ebay with no luck.

The cylinder bores didn't need to be ridge reamed, so I guess that means that the piston rings hadn't really worn down the bores...

I'm about to put HR pistons in, and I got a feeler gauge that goes down to 0.0025", but the fsm states that the piston to cylinder bore clearance is to be between 0.0004 - 0.0012"? The 0.0025" feeler gauge is TWICE that thickness and it's paper-thin steel, so how do I measure? Are there some other kinds of feeler gauge that go down to 0.0004 - 0.0012" I searched on ebay with no luck.

#22

Just make sure you use new rings, measure up the pistons (skirt and crown) and match them up (largest/smallest) to the corresponding cylinders. Greater chance of cold start piston slap, but just play with oils later on - it'll probably be right at the limit of being within spec. Either you're actually dropping some coin, buying oversize pistons and giving them to a machinist to match to the block with a certain tolerance request, or doing what you're doing and working with what you've got. If you can't get 1 or 2 of them comfortably close to within spec, you can always buy a new HR piston or 2 on the cheap.

#23

I just honed the cylinders, and I don't really have the 'ideal' 60 degree crosshatch, more like 45-50 degree, but will that matter?

The cylinder bores didn't need to be ridge reamed, so I guess that means that the piston rings hadn't really worn down the bores...

I'm about to put HR pistons in, and I got a feeler gauge that goes down to 0.0025", but the fsm states that the piston to cylinder bore clearance is to be between 0.0004 - 0.0012"? The 0.0025" feeler gauge is TWICE that thickness and it's paper-thin steel, so how do I measure? Are there some other kinds of feeler gauge that go down to 0.0004 - 0.0012" I searched on ebay with no luck.

The cylinder bores didn't need to be ridge reamed, so I guess that means that the piston rings hadn't really worn down the bores...

I'm about to put HR pistons in, and I got a feeler gauge that goes down to 0.0025", but the fsm states that the piston to cylinder bore clearance is to be between 0.0004 - 0.0012"? The 0.0025" feeler gauge is TWICE that thickness and it's paper-thin steel, so how do I measure? Are there some other kinds of feeler gauge that go down to 0.0004 - 0.0012" I searched on ebay with no luck.

Ridge reaming is about cleaning up the carbon on the top of the bores so you can put new slugs in.

Feeler gauges are just about the worst way to measure piston-bore clearances. You're supposed to use a mic and bore gauge and measure at several points. Performance engines are supposed to be on the loose side.

#24

Pistons don't wear on the block. It's the other way around. The pistons are made of aluminum and the bores are made of cast iron. Cast iron is much harder than Al.

#25

Just make sure you use new rings, measure up the pistons (skirt and crown) and match them up (largest/smallest) to the corresponding cylinders. Greater chance of cold start piston slap, but just play with oils later on - it'll probably be right at the limit of being within spec. Either you're actually dropping some coin, buying oversize pistons and giving them to a machinist to match to the block with a certain tolerance request, or doing what you're doing and working with what you've got. If you can't get 1 or 2 of them comfortably close to within spec, you can always buy a new HR piston or 2 on the cheap.

So the other way around then, let me rephrase: What harm would come to the undersize pistons? Just piston slap? Or is there any other harm that can occur that I'm failing to ask about? Or am I just concerned over nothing much here and should I just use the pistons that I have?

#26

Yes, I used brand new DE rings on the used HR pistons. (the DE oil rings are a little bigger than the HR oil rings, so I am reusing the oil rings from the HR pistons) I am working with what I've got unfortunately, so I might need a couple new grade 2's and a new grade 3.. will this be ok to use with the three used grade 2 HR pistons?

[QUOTE=Maximeltman;8360063]

If it's a little difficult to get the slug in the bore, it's probably got close to the right clearance. If it's looser than a ***** and it just drops in without any finagling, it's got too much clearance.

For instance....

That is a GM motor that has a good 1/8" of clearance. That's 125/1000." That's a sh!tton of clearance.

Also, the HR pistons are asymmetrical and you need to position them correctly too. IIRC, the bigger skirt goes towards the exhaust. But don't quote me on it-I'm writing this after a few beers.

Last edited by Weimar Ben; 02-12-2012 at 06:49 PM.

#27

Ouch...I just bought these DE rings and already installed them. Do you think these new DE rings are the same rings with that sealing issue, I thought/figured why would Nissan still sell them if they're garbage lol Do You think I have a chance at returning them because they still look like new... Are the HR rings made of the same material?

Your link didn't appear, but I have been reading about that GM issue. Sucks that happens from factory. The pistons seemed kinda snug-fitting so that's a good thing...but I might get three new ones..very very cold in the garage so clearances may be off a bit.

Your link didn't appear, but I have been reading about that GM issue. Sucks that happens from factory. The pistons seemed kinda snug-fitting so that's a good thing...but I might get three new ones..very very cold in the garage so clearances may be off a bit.

#28

Garbage? Companies, including Nissan, knowingly put out garbage all the time if they think they can get away with it. Just look at the 5spd manual tranny or 2.5L engine. Their goal is not to put out perfect products, but to make as much money as possible.

As for the cold, you haven't lived until you've experienced -60*F in Alaska. My 3.5 with HR pistons with 0w-30 actually started up unassisted at that temperature. I had timing chain noise for about a minute though.

Last edited by Weimar Ben; 02-12-2012 at 07:22 PM.

#29

hmmm...yes I believe I'm going to at least try to exchange them, I have it all apart now so why not? Worst case scenario they won't let me, then I'll just use them. I might also bite the bullet get the two grade#2 and one grade#3 pistons though. I already installed these rings and pistons btw, and torqued the girdle down and everything, but Then I got worried because I remembered that the main journals had lint on them from me cleaning without a lint free cloth. When I pulled out the pistons, there were tiny slivers of the cylinder bore metal on the rings(I spun the engine by hand to align the piston rods to journals.) that metal has been removed, glad I caught that.

#30

The HR rings (2nd ring IIRC) has a much more aggressive under hook design - and don't forget, everything in the HR is designed for a higher rev limit from the factory if that matters to you.

Assuming you haven't measured .....don't get too caught up on the grade stamps - the block was used and honed. Things change, you need actual measurements. Chances are the pistons are close to the indicated size (stamped on the block they came out of) - but to measure the bore, it really helps to have a bore gauge - even if its just the telescopic 't' kind that you lock and use a caliper to measure from. You can get a cheap set for around 30 bucks. It's possible to use a ring to measure (using a feeler gauge in the gap), but its really hard to get consistent readings unless you have a way to keep each part (12-3-6-9'oclock) lined up.

Assuming you haven't measured .....don't get too caught up on the grade stamps - the block was used and honed. Things change, you need actual measurements. Chances are the pistons are close to the indicated size (stamped on the block they came out of) - but to measure the bore, it really helps to have a bore gauge - even if its just the telescopic 't' kind that you lock and use a caliper to measure from. You can get a cheap set for around 30 bucks. It's possible to use a ring to measure (using a feeler gauge in the gap), but its really hard to get consistent readings unless you have a way to keep each part (12-3-6-9'oclock) lined up.

#31

Yea, I can see the underhook you speak of on the HR ring, very slight but it's there. The DEs don't have one at all it seems, that's why theyre unidirectional and the HR have a stamp on them indicating one way install. I am going to try to exchange them. I hope they will take them back.

Thread

Thread Starter

Forum

Replies

Last Post

jmlee44

4th Generation Maxima (1995-1999)

8

10-02-2022 02:13 PM

My Coffee

New Member Introductions

15

06-06-2017 02:01 PM

CAN-Toronto FS: Basement cleaning

knight_yyz

5th Generation Classifieds (2000-2003)

12

11-01-2015 01:34 PM