Replacing Alternator

#124

sux......So my fiancee was driving her car yesterday, after using this thread to replace her alternator, and the car died again...It was driving fine on the new alternator for around 3 weeks....

Brand new battery, and new(reman) alternator. And the car shut off.

I showed up, and got in, started the car and revved it a little. Car was fine while my foot was keeping revs above 1000rpm, but when the revs droppped below that, the car would shut off? Anyone? I am lost. I don't get how the car runs above 1000rpm, but then shuts off when I let it idle/take my foot off the gas? Could the 'new' alternator be bad, and if so, would it cause this?

here we go again...

Brand new battery, and new(reman) alternator. And the car shut off.

I showed up, and got in, started the car and revved it a little. Car was fine while my foot was keeping revs above 1000rpm, but when the revs droppped below that, the car would shut off? Anyone? I am lost. I don't get how the car runs above 1000rpm, but then shuts off when I let it idle/take my foot off the gas? Could the 'new' alternator be bad, and if so, would it cause this?

here we go again...

Last edited by chisai88; 04-08-2010 at 09:21 AM.

#126

well, it got towed to the dealer yesterday. They said there was a code for a bad MAF and that then they would try to relearn the idle. They did that, and now they are saying the idle motor is bad, and that it also fried the ECM...

They are going to get back to me, but what the (*&#. That is going to be more than $1K if they do the work...I guess I will see what they say, but what a pain in the ***...Where can I get a new/reman ECM online for a 2000 maxima, if I need one?

They are going to get back to me, but what the (*&#. That is going to be more than $1K if they do the work...I guess I will see what they say, but what a pain in the ***...Where can I get a new/reman ECM online for a 2000 maxima, if I need one?

#127

also, anyone in VA that has a scan tool, and want to have a few beers while I do this. Then I won't need to get it towed back to the dealer to get reprogrammed...If I need a new ECM, but I am sure they are going to tell me that.

#128

you know.... there is a huge thread on the org about the electronic motor mounts our auto maxis have and how upon failure they fry the iacv and ecu/ecm.

I would strongly suggest to get the work done and also disconnect your electronic motor mounts.

I have been debating and putting off swapping out my electronic mounts for a set of manual ones... but your incident just made me say... get it done my end of the month.

I would strongly suggest to get the work done and also disconnect your electronic motor mounts.

I have been debating and putting off swapping out my electronic mounts for a set of manual ones... but your incident just made me say... get it done my end of the month.

#131

They are fluid-filled mounts, electronically controlled, that get soft when the engine is at idle speed and hard at higher speeds. In our cars, only the ones with automatic transmissions come with these type of mounts (front and back mounts only).

#133

^^From what I've read, when they fail they fry the ECU along with them. A lot of people opt for disconnecting them and just taping the harnesses, since they do not throw a SES light, to avoid expensive ECU replacement when they go south. Supposedly they give you warning signs, such as a particular buzzing sound, before they fail. I guess leakage of the mounts themselves is another sign.

Other people prefer to replace them for manual mounts and not have to worry about the electronic ones shorting the ECU. The only drawback is some excesive vibration that one have to get used to.

There's plenty of information in these forums about that, in case you want to dig a little deeper (before we get flamed for hijacking or whoring this thread... )

)

Other people prefer to replace them for manual mounts and not have to worry about the electronic ones shorting the ECU. The only drawback is some excesive vibration that one have to get used to.

There's plenty of information in these forums about that, in case you want to dig a little deeper (before we get flamed for hijacking or whoring this thread...

)

)

Last edited by Nelsito65; 04-13-2010 at 05:56 PM.

#135

Alternator replacement

I am trying to replace my alternator and the link to motorvate.ca isn't working anymore and most of whoever has replaced it have directed me to this link,

http://www.motorvate.ca/mvp.php/500

and it seems to be broken.

I am not sure if anyone of you saved the procedure from that website, if you did , i would really appreciate if you could share it with me or direct me to a working link

Thank you

http://www.motorvate.ca/mvp.php/500

and it seems to be broken.

I am not sure if anyone of you saved the procedure from that website, if you did , i would really appreciate if you could share it with me or direct me to a working link

Thank you

#136

I am trying to replace my alternator and the link to motorvate.ca isn't working anymore and most of whoever has replaced it have directed me to this link,

http://www.motorvate.ca/mvp.php/500

and it seems to be broken.

I am not sure if anyone of you saved the procedure from that website, if you did , i would really appreciate if you could share it with me or direct me to a working link

Thank you

http://www.motorvate.ca/mvp.php/500

and it seems to be broken.

I am not sure if anyone of you saved the procedure from that website, if you did , i would really appreciate if you could share it with me or direct me to a working link

Thank you

#138

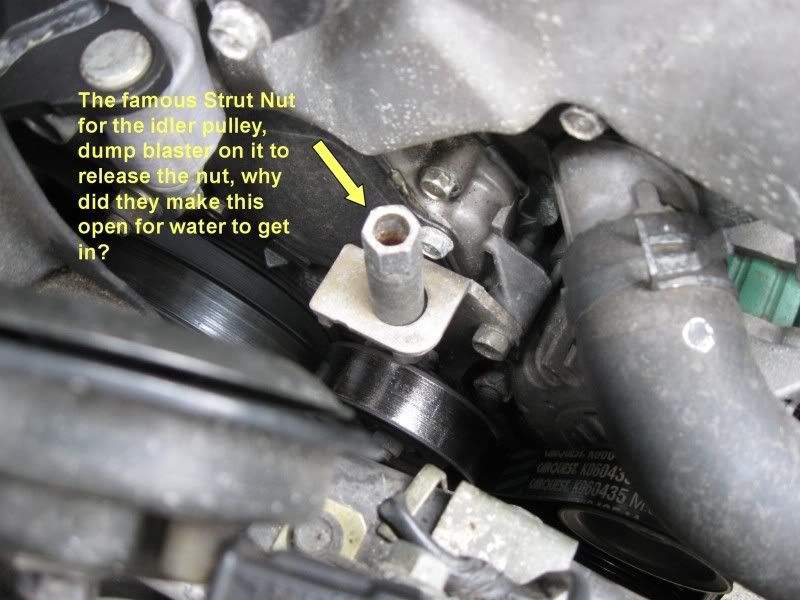

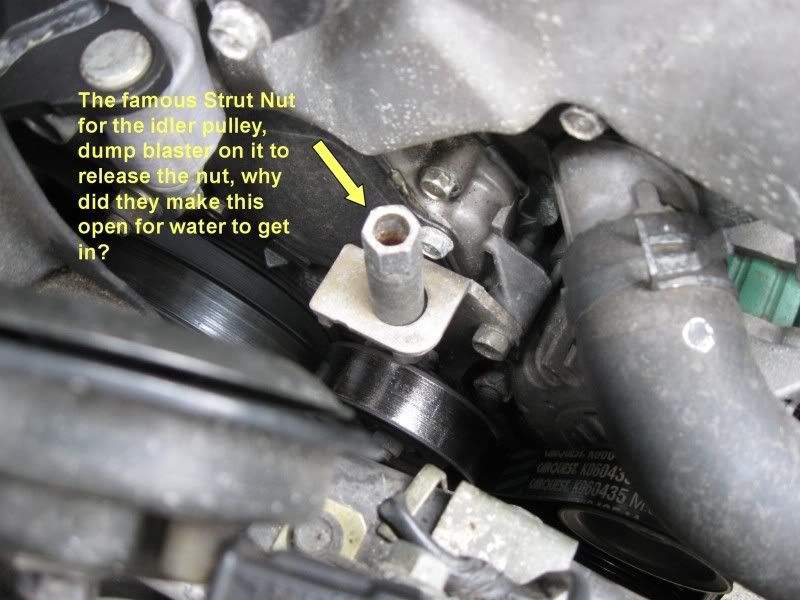

I suspect I have to change the alternator and AC clutch bearing on my '03. Finally got the shop cleared out to be able to work inside. Monday I had a quick try to turn the tensioner "strut nut"

but it didn't move easily. I put some oil in it and went back to tidying up. I just want to make sure, there is no lock nut on it is there? As I understand it from here this nut should turn down and then you slacken off the tensioner holding nut (lower down) to actually get the tension pulley to move then? I know this sounds pretty "newby" but I sure don't want to strip/shear anything. The car's inside now, so today's the day to have at it. I'm thinking I might just put the new belt on first so I can diagnose things properly.

Thanks in advance. Andrew

but it didn't move easily. I put some oil in it and went back to tidying up. I just want to make sure, there is no lock nut on it is there? As I understand it from here this nut should turn down and then you slacken off the tensioner holding nut (lower down) to actually get the tension pulley to move then? I know this sounds pretty "newby" but I sure don't want to strip/shear anything. The car's inside now, so today's the day to have at it. I'm thinking I might just put the new belt on first so I can diagnose things properly.

Thanks in advance. Andrew

#139

I suspect I have to change the alternator and AC clutch bearing on my '03. Finally got the shop cleared out to be able to work inside. Monday I had a quick try to turn the tensioner "strut nut"

but it didn't move easily. I put some oil in it and went back to tidying up. I just want to make sure, there is no lock nut on it is there? As I understand it from here this nut should turn down and then you slacken off the tensioner holding nut (lower down) to actually get the tension pulley to move then? I know this sounds pretty "newby" but I sure don't want to strip/shear anything. The car's inside now, so today's the day to have at it. I'm thinking I might just put the new belt on first so I can diagnose things properly.

Thanks in advance. Andrew

but it didn't move easily. I put some oil in it and went back to tidying up. I just want to make sure, there is no lock nut on it is there? As I understand it from here this nut should turn down and then you slacken off the tensioner holding nut (lower down) to actually get the tension pulley to move then? I know this sounds pretty "newby" but I sure don't want to strip/shear anything. The car's inside now, so today's the day to have at it. I'm thinking I might just put the new belt on first so I can diagnose things properly.

Thanks in advance. Andrew

Last edited by Nelsito65; 05-19-2010 at 10:46 AM.

#141

Thanks everyone.

All was clear when I went back down. Got it loosened off (not without trouble and tension) and a new belt in position. I guess I released the tension just a bit too far and jammed at the end of the thread. Damn adjuster rod sheared off when I tried to re-tension. So now the whole thing is off and I'm about to start phoning to find out how much extra this is going to put me back. With the adjuster (strut) nut and thread being left hand it's more of a pain to fab up an alternative.

If it's not one damn thing, it's another damn thing.

cheers, Andrew

All was clear when I went back down. Got it loosened off (not without trouble and tension) and a new belt in position. I guess I released the tension just a bit too far and jammed at the end of the thread. Damn adjuster rod sheared off when I tried to re-tension. So now the whole thing is off and I'm about to start phoning to find out how much extra this is going to put me back. With the adjuster (strut) nut and thread being left hand it's more of a pain to fab up an alternative.

If it's not one damn thing, it's another damn thing.

cheers, Andrew

#142

Replacement tensioner rod is only available from dealer as part of a new idler assembly for $123, and not until Friday. So I re-tapped the "strut nut" 5/16 NC (instead of the 7mm left hand, or whatever it is), welded a chunk of threaded rod onto the bottom part of the tension rod and put it all back together. Right now everything **seems** to be working OK and charging, although the AC clutch was rubbing somewhere before I put the belt on. If it keeps going OK, I can return the alternator and use the money towards either the AC clutch or some brake parts.

Thanks again. Andrew

Thanks again. Andrew

#146

HUGE thank you to those who have contributed in this thread. I just got done replacing the alternator in my '00 with 160k miles (original alt!). Everything went very smoothly thanks to the tips/tricks in this thread.

I first noticed something was up 2 days ago when I thought there was an odd whine coming from the car. I suspected power steering (it's been feeling a little different lately) and was planning to change the fluid this weekend to see if it helped at all. When I was out running errands today the car wouldn't start after going into Staples....at that point I pretty much knew the alternator was what the whining sound had been the whole time.

I got a jump start from a friend and on the way back home my dashboard started lighting up like a christmas tree. tcs off, brake, batt, airbag, seat belt, you name it.

$128 plus tax and 2.5 hours of work and the job is done. Too easy! I got my alternator from advanceauto.com and used code sp20 to save 20%. Perfect fit too. Also, I didn't have to replace the tensioner pulley nut...I used liquid wrench on it an hour before I started and then was pretty careful with a 14mm box wrench.

I do have one question though -- should I be concerned if the new alternator is only charging at 13.9 volts? The battery connectors are not corroded at all but there is quite a bit of grease on the terminals from the last guy. Maybe I need to clean everything up a bit...

I first noticed something was up 2 days ago when I thought there was an odd whine coming from the car. I suspected power steering (it's been feeling a little different lately) and was planning to change the fluid this weekend to see if it helped at all. When I was out running errands today the car wouldn't start after going into Staples....at that point I pretty much knew the alternator was what the whining sound had been the whole time.

I got a jump start from a friend and on the way back home my dashboard started lighting up like a christmas tree. tcs off, brake, batt, airbag, seat belt, you name it.

$128 plus tax and 2.5 hours of work and the job is done. Too easy! I got my alternator from advanceauto.com and used code sp20 to save 20%. Perfect fit too. Also, I didn't have to replace the tensioner pulley nut...I used liquid wrench on it an hour before I started and then was pretty careful with a 14mm box wrench.

I do have one question though -- should I be concerned if the new alternator is only charging at 13.9 volts? The battery connectors are not corroded at all but there is quite a bit of grease on the terminals from the last guy. Maybe I need to clean everything up a bit...

Last edited by slyk; 05-22-2010 at 07:58 PM.

#149

#151

HUGE thank you to those who have contributed in this thread. I just got done replacing the alternator in my '00 with 160k miles (original alt!). Everything went very smoothly thanks to the tips/tricks in this thread.

I first noticed something was up 2 days ago when I thought there was an odd whine coming from the car. I suspected power steering (it's been feeling a little different lately) and was planning to change the fluid this weekend to see if it helped at all. When I was out running errands today the car wouldn't start after going into Staples....at that point I pretty much knew the alternator was what the whining sound had been the whole time.

I got a jump start from a friend and on the way back home my dashboard started lighting up like a christmas tree. tcs off, brake, batt, airbag, seat belt, you name it.

$128 plus tax and 2.5 hours of work and the job is done. Too easy! I got my alternator from advanceauto.com and used code sp20 to save 20%. Perfect fit too. Also, I didn't have to replace the tensioner pulley nut...I used liquid wrench on it an hour before I started and then was pretty careful with a 14mm box wrench.

I do have one question though -- should I be concerned if the new alternator is only charging at 13.9 volts? The battery connectors are not corroded at all but there is quite a bit of grease on the terminals from the last guy. Maybe I need to clean everything up a bit...

I first noticed something was up 2 days ago when I thought there was an odd whine coming from the car. I suspected power steering (it's been feeling a little different lately) and was planning to change the fluid this weekend to see if it helped at all. When I was out running errands today the car wouldn't start after going into Staples....at that point I pretty much knew the alternator was what the whining sound had been the whole time.

I got a jump start from a friend and on the way back home my dashboard started lighting up like a christmas tree. tcs off, brake, batt, airbag, seat belt, you name it.

$128 plus tax and 2.5 hours of work and the job is done. Too easy! I got my alternator from advanceauto.com and used code sp20 to save 20%. Perfect fit too. Also, I didn't have to replace the tensioner pulley nut...I used liquid wrench on it an hour before I started and then was pretty careful with a 14mm box wrench.

I do have one question though -- should I be concerned if the new alternator is only charging at 13.9 volts? The battery connectors are not corroded at all but there is quite a bit of grease on the terminals from the last guy. Maybe I need to clean everything up a bit...

#153

http://en.wikipedia.org/wiki/Lead%E2%80%93acid_battery 'Voltages for common usages' section. It also gives voltage temperature dependency coefficient which gives approx +0.7 V increase if the temperature falls to 0F. So it is meaningless to talk about battery voltage without being specific about temperature, the range becomes too wide. Alternator has this dependency built it into its charging circuit so temp must be taken into account when comparing actual voltage with 'ideal' one. You can of course ignore all of this and just check it is not below some very low (13.9V) or very high threshold (14.6V) but then again it might not last that long. See p.3 from that Wiki article.

#155

One common place:

http://en.wikipedia.org/wiki/Lead%E2%80%93acid_battery 'Voltages for common usages' section. It also gives voltage temperature dependency coefficient which gives approx +0.7 V increase if the temperature falls to 0F. So it is meaningless to talk about battery voltage without being specific about temperature, the range becomes too wide. Alternator has this dependency built it into its charging circuit so temp must be taken into account when comparing actual voltage with 'ideal' one. You can of course ignore all of this and just check it is not below some very low (13.9V) or very high threshold (14.6V) but then again it might not last that long. See p.3 from that Wiki article.

http://en.wikipedia.org/wiki/Lead%E2%80%93acid_battery 'Voltages for common usages' section. It also gives voltage temperature dependency coefficient which gives approx +0.7 V increase if the temperature falls to 0F. So it is meaningless to talk about battery voltage without being specific about temperature, the range becomes too wide. Alternator has this dependency built it into its charging circuit so temp must be taken into account when comparing actual voltage with 'ideal' one. You can of course ignore all of this and just check it is not below some very low (13.9V) or very high threshold (14.6V) but then again it might not last that long. See p.3 from that Wiki article.

<sarcasm>

Will you measure the temperature of every cell's electrolyte too when calculating the perfect charging voltage too, or is "ambient temperature" your measure? Are the factors multiplicative or additive? The ambient temperature of the air outside? Under the hood? The voltage regulator temperature? Will you consider the voltage induction, if any, from a nearby high voltage line, electrical storm, or temperature differential themocoupling effect?

Good luck explaining that to the Nissan parts guy when you want to return your alternator on warranty because it is off by .0043V, just sayin'. I want to see that on YouTube. Or you changing the alternator at 0F.

</sarcasm>

Back to the topic, your charge voltage is fine if it's in the range stated in the FSM. Moreover, it will be on the low end initially, simply because it's charging the battery that's probably low or not fully charged. You know, the reason the alternator was changed in the first place.

#156

You know, it's possible to overthink a problem. Really. Unless I take your post to mean you'd really change the alternator when the temperature is 0F, and have enough manual dexterity left to operate the voltmeter after.

<sarcasm>

Will you measure the temperature of every cell's electrolyte too when calculating the perfect charging voltage too, or is "ambient temperature" your measure? Are the factors multiplicative or additive? The ambient temperature of the air outside? Under the hood? The voltage regulator temperature? Will you consider the voltage induction, if any, from a nearby high voltage line, electrical storm, or temperature differential themocoupling effect?

Good luck explaining that to the Nissan parts guy when you want to return your alternator on warranty because it is off by .0043V, just sayin'. I want to see that on YouTube. Or you changing the alternator at 0F.

</sarcasm>

Back to the topic, your charge voltage is fine if it's in the range stated in the FSM. Moreover, it will be on the low end initially, simply because it's charging the battery that's probably low or not fully charged. You know, the reason the alternator was changed in the first place.

<sarcasm>

Will you measure the temperature of every cell's electrolyte too when calculating the perfect charging voltage too, or is "ambient temperature" your measure? Are the factors multiplicative or additive? The ambient temperature of the air outside? Under the hood? The voltage regulator temperature? Will you consider the voltage induction, if any, from a nearby high voltage line, electrical storm, or temperature differential themocoupling effect?

Good luck explaining that to the Nissan parts guy when you want to return your alternator on warranty because it is off by .0043V, just sayin'. I want to see that on YouTube. Or you changing the alternator at 0F.

</sarcasm>

Back to the topic, your charge voltage is fine if it's in the range stated in the FSM. Moreover, it will be on the low end initially, simply because it's charging the battery that's probably low or not fully charged. You know, the reason the alternator was changed in the first place.

Batteries are also very asymmetric load - while it can provide huge current when being discharged it takes much less current to drive voltage up when charging. My point is - 13.9V seems too low unless it was extremely hot or engine wasn't running at 1k rpm.

Good alternator should have no problem to drive it to 14.4V at 1k rpm even fully discharged. There was a thread here in the past when thick wire going from alternator to the battery was getting very hot because of high charging current from alt. In that case one of the battery cells shortened and it made alt produce high charging current. The insulation on that wire was literally smoking.

#157

Okay, now I've done it. I've stripped the tensioner pulley nut and can't figure out how to get it off. The nut removers I have won't fit in that space. I don't think a nutcracker will work because of the washer part of the nut (or will it?). I'm at a loss. Any ideas. I stripped it with a box-end, by the way. After applying a bunch of Blaster. That guy won't budge...

Oh, and thank you guys for this and everything else on this site. I've been a lurker for a few years, and this community is awesome!

Oh, and thank you guys for this and everything else on this site. I've been a lurker for a few years, and this community is awesome!

#158

Okay, now I've done it. I've stripped the tensioner pulley nut and can't figure out how to get it off. The nut removers I have won't fit in that space. I don't think a nutcracker will work because of the washer part of the nut (or will it?). I'm at a loss. Any ideas. I stripped it with a box-end, by the way. After applying a bunch of Blaster. That guy won't budge...

Oh, and thank you guys for this and everything else on this site. I've been a lurker for a few years, and this community is awesome!

Oh, and thank you guys for this and everything else on this site. I've been a lurker for a few years, and this community is awesome!

#159

Yeah, I guess that wasn't clear. I'm talking about the nut on the pulley, not the tensioning nut. I think today I'm going to try to modify a Bolt-Out to fit in that space, or file the nut down and crack it. Is the tension pulley assembly easy to replace if I foul the threads?

#160

Yeah, I guess that wasn't clear. I'm talking about the nut on the pulley, not the tensioning nut. I think today I'm going to try to modify a Bolt-Out to fit in that space, or file the nut down and crack it. Is the tension pulley assembly easy to replace if I foul the threads?