How do I cut off this pivot joint on wheel hub?

#1

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

How do I cut off this pivot joint on wheel hub?

Problem solved.

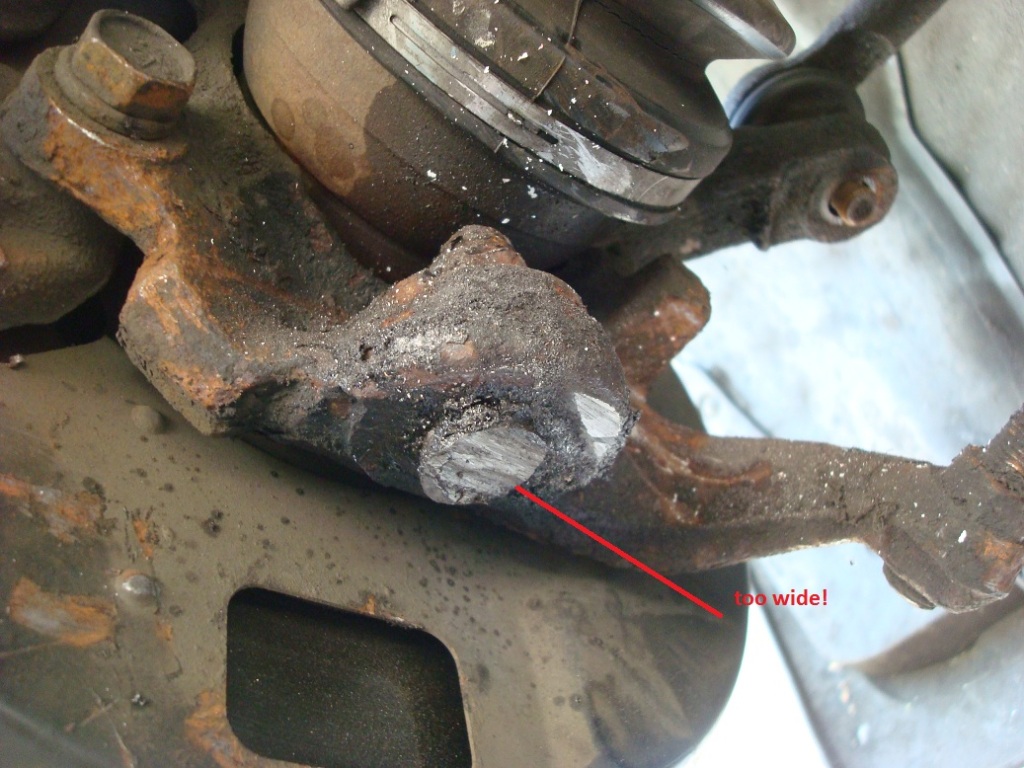

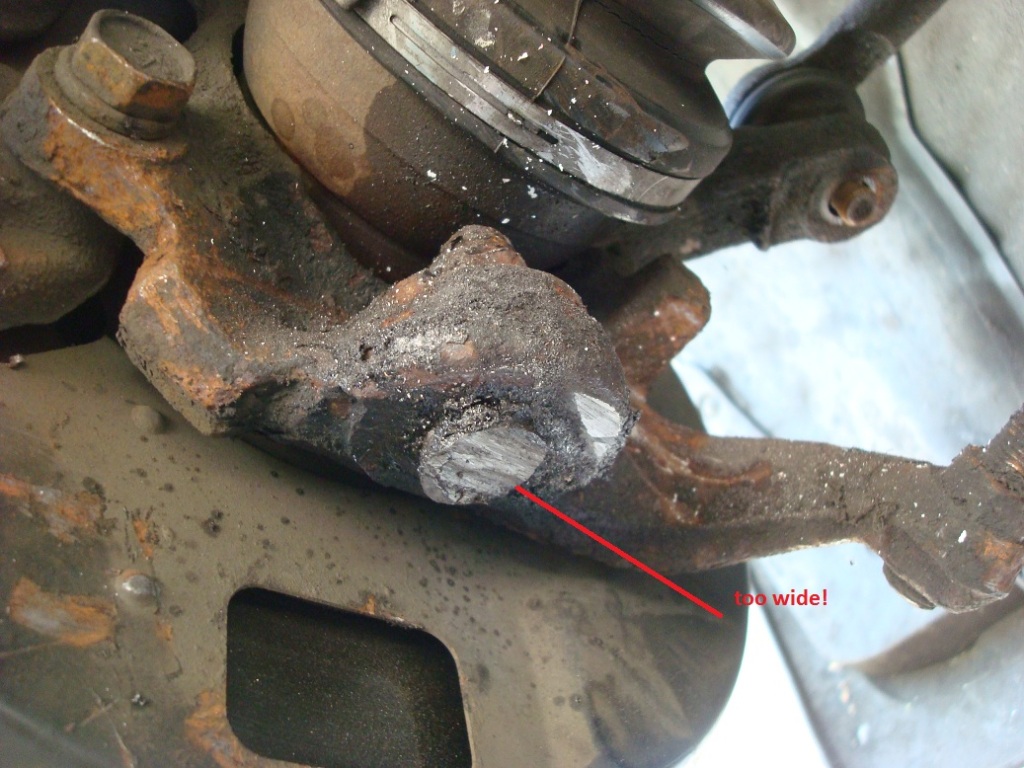

Started removing control arms for replacement...ran into this problem.

I didnt bother removing the axle nut because 1) the nut in the pictures is rusted/fused to the bolt and 2) Even a 19mm wrench stripped/rounded the nut.

So i attempted to cut it, I used a saw-zaw on the bottom end, where there was more clearance, and I didnt realize until after, that the bolt got thicker as it traveled down. Now im trying to cut the top, with little space, and its become a obstacle I am unaware how to tackle. I'm running out of blades...

Any ideas? Im guessing my only options are:

1) remove axle, grind it with a grinder.

2) get new wheel hub...god knows where for how much.

Started removing control arms for replacement...ran into this problem.

I didnt bother removing the axle nut because 1) the nut in the pictures is rusted/fused to the bolt and 2) Even a 19mm wrench stripped/rounded the nut.

So i attempted to cut it, I used a saw-zaw on the bottom end, where there was more clearance, and I didnt realize until after, that the bolt got thicker as it traveled down. Now im trying to cut the top, with little space, and its become a obstacle I am unaware how to tackle. I'm running out of blades...

Any ideas? Im guessing my only options are:

1) remove axle, grind it with a grinder.

2) get new wheel hub...god knows where for how much.

Last edited by shadyonedeath; 04-03-2012 at 05:14 PM.

#2

Looks like a torch some pb blaster and a chisel are going to help out. Lots of people use a chisel to loosen a stripped injector screw. In the future, since you obviously have problems with rust, spray pb liberally and then torch it for a few mins then go at it. BTW a cut-off wheel works better on nuts/bolts than a SAWZALL

#8

#10

air chisel will have that out in .2 sec's...

or

http://www.cdxetextbook.com/images/c...flatChisel.jpg

with a bfh

or

http://www.cdxetextbook.com/images/c...flatChisel.jpg

with a bfh

#12

Member who somehow became The President of The SE-L Club

iTrader: (19)

Join Date: Jun 2001

Posts: 16,033

1) you should have taken the axle out so you had room to work.

2) looking at the corrosion, heat was your only option.

3) Get an Acetylene touch, heat the nut till it glows red and it would have come off like butter.

The joint is tapered, it will never push up from the bottom.

Step away from the vehicle and do some research or let a mechanic finish the job for you.

With the right equipment, the ball joint removal would have been a 5 minute job.

2) looking at the corrosion, heat was your only option.

3) Get an Acetylene touch, heat the nut till it glows red and it would have come off like butter.

The joint is tapered, it will never push up from the bottom.

Step away from the vehicle and do some research or let a mechanic finish the job for you.

With the right equipment, the ball joint removal would have been a 5 minute job.

#13

why have you been attempting all this crap without removing the axle? you've kind of painted yourself into a corner now.

remove the damn axle first. cut it off with a cut off wheel if you have one. heat the **** out of the knuckle with a torch, air hammer straight down on the remains of the ball joint and i bet you get it out. nut splitter would probably have worked too, as would a cutting torch, as would a sacrifice socket.

or you could just go pick up another steering knuckle for like $50.

the word is "sawzall" by the way, because it "saws all things". that joint is the ball joint.

remove the damn axle first. cut it off with a cut off wheel if you have one. heat the **** out of the knuckle with a torch, air hammer straight down on the remains of the ball joint and i bet you get it out. nut splitter would probably have worked too, as would a cutting torch, as would a sacrifice socket.

or you could just go pick up another steering knuckle for like $50.

the word is "sawzall" by the way, because it "saws all things". that joint is the ball joint.

#15

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

why have you been attempting all this crap without removing the axle? you've kind of painted yourself into a corner now.

remove the damn axle first. cut it off with a cut off wheel if you have one. heat the **** out of the knuckle with a torch, air hammer straight down on the remains of the ball joint and i bet you get it out. nut splitter would probably have worked too, as would a cutting torch, as would a sacrifice socket.

or you could just go pick up another steering knuckle for like $50.

the word is "sawzall" by the way, because it "saws all things". that joint is the ball joint.

remove the damn axle first. cut it off with a cut off wheel if you have one. heat the **** out of the knuckle with a torch, air hammer straight down on the remains of the ball joint and i bet you get it out. nut splitter would probably have worked too, as would a cutting torch, as would a sacrifice socket.

or you could just go pick up another steering knuckle for like $50.

the word is "sawzall" by the way, because it "saws all things". that joint is the ball joint.

because when SEARCHING, many people said you did NOT need to take the axle off. Lots of mis-information on here then...because one of them was also a moderator.

Last edited by shadyonedeath; 04-03-2012 at 10:26 AM.

#16

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

Got that ***** out. +1 for the .org. Thanks guys, now for the other side! :P

Anyone install suspension components without a torque wrench? How'd that go? Also, the alignment place will adjust my inner tie to tie rod end, right? To proper specs?

Anyone install suspension components without a torque wrench? How'd that go? Also, the alignment place will adjust my inner tie to tie rod end, right? To proper specs?

#17

Started removing control arms for replacement...ran into this problem.

I didnt bother removing the axle nut because 1) the nut in the pictures is rusted/fused to the bolt and 2) Even a 19mm wrench stripped/rounded the nut.

So i attempted to cut it, I used a saw-zaw on the bottom end, where there was more clearance, and I didnt realize until after, that the bolt got thicker as it traveled down. Now im trying to cut the top, with little space, and its become a obstacle I am unaware how to tackle. I'm running out of blades...

I didnt bother removing the axle nut because 1) the nut in the pictures is rusted/fused to the bolt and 2) Even a 19mm wrench stripped/rounded the nut.

So i attempted to cut it, I used a saw-zaw on the bottom end, where there was more clearance, and I didnt realize until after, that the bolt got thicker as it traveled down. Now im trying to cut the top, with little space, and its become a obstacle I am unaware how to tackle. I'm running out of blades...

2 Its called a ball joint

3 Never use an open end wrench on a rusted and tight bolt.

4 Always remove the axle first and use a SIX point socket.

5 Ball joints are tapered

6 heat is your friend, but not you CV boots friend

7 Spend more time studying any particular aspect before attempting repairs.

8 It's not a wheel hub, its a steering knuckle.

No sir, you are a douche. Its people like you that perpetuate the opinion the "only mechanics should work on cars". If you cant take some constructive criticism, don't fukc your car up and then tell us about it. Ask for help before you start and dont take shortcuts untill you have some experience under yout belt.

#20

ive changed my balljoints 2 weeks ago without removing my axle...i took the entire strut assembly out and loosened the balljoint nut with vice grips and a 16 oz hammer first then a BALL JOINT SEPERATOR to free the shaft.up then banged it down enough to remove the nut...afterwards a BALL JOINT PRESS becomes your friend...just sayin.. its easier if.you have the right tools to start... i been.down that road before and.it sucks having to search for something to "make work". just research more beforehand is all people are sayin...glad you got.it fixed tho

#22

There is also a C clip or ring, or whatever its called holding the bottom of the balljoint against the control arm IIRC, no one mentioned that. Now u probably should post how you resolved the problem to help others in the future.

#24

oh goodness this progressed pretty far since I posted lol. For future readers, a torch should be in your tool box as well as some sort of penetrating product(lol) to spray on before you even start. A ball joint is just a pain to remove with hand tools but its not impossible

#25

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

Hows it looking? I found bought a Snap on torque wrench but the lowest it goes is 50ft/lbs. It was useful for the larger 22mm bolts, ball joint and inner/outer tie rod, but not so much for the end link.

This helped.

Anything appear TOO tight?

This helped.

Anything appear TOO tight?

Last edited by shadyonedeath; 04-03-2012 at 05:23 PM.

#28

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

It like this one at 10:05 http://www.youtube.com/watch?v=yTIePKbH3hY

So..back to the pics. Do my ball joints appear too tight?

So..back to the pics. Do my ball joints appear too tight?

Last edited by shadyonedeath; 04-03-2012 at 05:53 PM.

#30

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

it was locally, 2nd hand.

Can any of this be adjusted by my aligment place? Like the fine-tuning of torque specs? As for the ball joints, if I loosen them up any more, the nut can just travel/spin with hand tightening...So thats why I kept going. Maybe this tool isn't so great.

Thanks for the help!

Can any of this be adjusted by my aligment place? Like the fine-tuning of torque specs? As for the ball joints, if I loosen them up any more, the nut can just travel/spin with hand tightening...So thats why I kept going. Maybe this tool isn't so great.

Thanks for the help!

#32

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

Time for a shower. Thanks for the help guys.

#33

I dont know for a fact but it would appear that way. Not many ball joint installs under my belt and none on a maxi pad. I know the boot shouldn't be bent like that,as it will tear more easily. Loosen it just enough to where the boot isn't crushed like that and see where you are. With the cotter pin, its not going anywhere anyways. THe bolt is merely to hold it in place so it doesn't move and allows smooth movement for the rotor assembly as intended

Last edited by ShocknAwe; 04-03-2012 at 09:08 PM.

#35

just a question but have you ever used a torque wrench before? reason i ask is because some of them take the right amount of finesse to hear the audible click telling you the torque spec is reached. and if youre trying to spin the wrench too hard youll miss the click.

#36

Senior Member

Thread Starter

iTrader: (10)

Join Date: Jul 2006

Location: Los Angeles, CA

Posts: 2,077

Im still trying to figure out if I should back off those castle nuts and just set them so the castle bridges sit right over the cotter pin hole.

#38

I could be mistaken but...

The ball join shaft has a tapered fit into the knuckle. How can overtightening the castle nut make it move in much farther than it can? Unless the knuckle splits. The taper is not so slight, IIRC. It seats where it will, you can't adjust the position.

Overtightening the castle nut could make separating the ball joint from the knuckle difficult the next time around.

The ball join shaft has a tapered fit into the knuckle. How can overtightening the castle nut make it move in much farther than it can? Unless the knuckle splits. The taper is not so slight, IIRC. It seats where it will, you can't adjust the position.

Overtightening the castle nut could make separating the ball joint from the knuckle difficult the next time around.

Thread

Thread Starter

Forum

Replies

Last Post

londonflu

3rd Generation Maxima (1989-1994)

40

09-25-2015 09:11 AM